The patented technology of preparing high performance hollow fiber ultrafiltration membrane is introduced. The hollow fiber ultrafiltration membrane produced by unique formulation and specific process has the characteristics of ultra-thin separation layer and typical spongy cross-section structure. It has higher tensile strength and elongation at break. At the same time, it has stronger hydrophilic retention performance and shows higher solution flux and stronger water treatment process. The technical advantages of pollution resistance and easy cleaning after pollution have essentially solved the problems of low strength and poor pollution resistance of existing hollow fiber ultrafiltration membranes.

Main Technical Indicators

Project | Size |

Membrane Materials | PVDF |

Standard Aperture(μm) | 0.02 |

ID/OD(mm) | 0.6/1.2 |

Pure Water Flux[L/(m2·h),0.1MPa] | 200-250 |

Solution Flux[L/(m2·h),0.10MPa] | 150~200 |

Normal Operating Pressure(MPa) | 0.05~0.10 |

Maximum Operating Pressure(MPa) | 0.30 |

Cleaning Cycle(min) | 60~120 |

Chlorine Tolerance | Excellent |

Solvent Resistance | Excellent |

Acid and Alkali Resistance | pH=2-13 |

Contact Angle | 42.6° |

Tensile Strength(MPa) | 4.3 |

Technical characteristics

Low operating cost: Under the same operating conditions, high performance hollow fiber ultrafiltration membrane has lower transmembrane operating pressure, can maintain low pressure and high throughput for a long time, and the backwashing cycle can be extended by more than 50%. It has obvious advantages of water saving (saving backwashing water), medicine saving (saving chemical backwashing agents, reducing secondary pollution to the environment), energy saving (reducing power consumption of pumps).

Low pressure and high flux: Under the same transmembrane pressure, the solution flux of high performance hollow fiber ultrafiltration membrane increased by more than 30%. It has outstanding performance in the measurement of porosity, pore size, pore size distribution and standard pure water flux.

Good anti fouling ability: as the high performance hollow fiber ultrafiltration membrane has a strong hydrophilic group on the surface, the hydrophilicity of the hollow fiber ultrafiltration membrane has been greatly improved. Its contact angle is less than 43 degrees, which reduces the pollution caused by hydrophobic pollutants. The enhanced hydrophilicity of the membrane makes it difficult to contaminate the membrane for a long time, even if the gel layer is polluted. Cleaning can be applied to the treatment of highly polluted wastewater. as the high performance hollow fiber ultrafiltration membrane has a strong hydrophilic group on the surface, the hydrophilicity of the hollow fiber ultrafiltration membrane has been greatly improved. Its contact angle is less than 43 degrees, which reduces the pollution caused by hydrophobic pollutants. The enhanced hydrophilicity of the membrane makes it difficult to contaminate the membrane for a long time, even if the gel layer is polluted. Cleaning can be applied to the treatment of highly polluted wastewater.

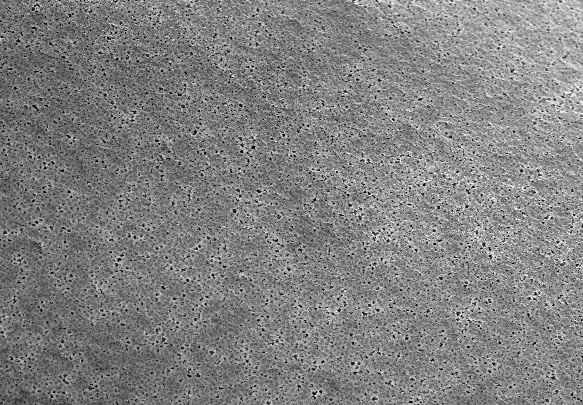

Outer Surface

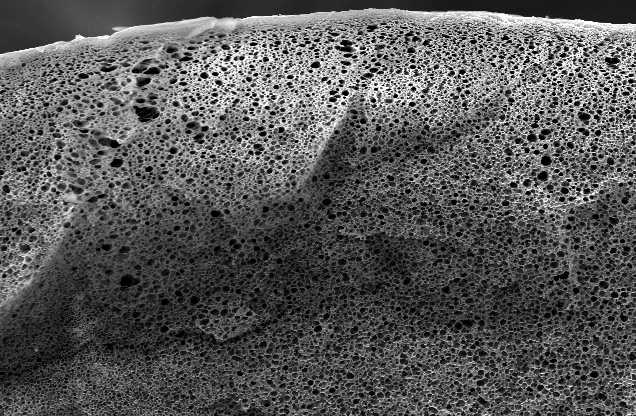

Cross-Section