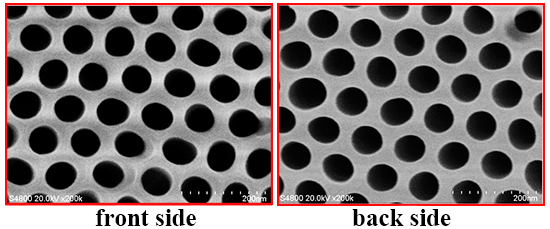

Isotropic AAO templates, often referring to thicker AAO to be different from ultrathin AAO membrane, are widely used for a number of different fields. Topmembranes technology is specialized to make high quality isotropic AAO templates, with highly uniform and regular pore on both sides of the surfaces. The pores are arranged hexagonally within the single grains of the aluminum. The translucent nature of AAO is appealing to applications in biomedical field.

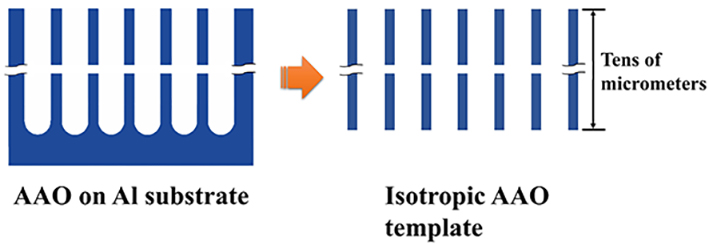

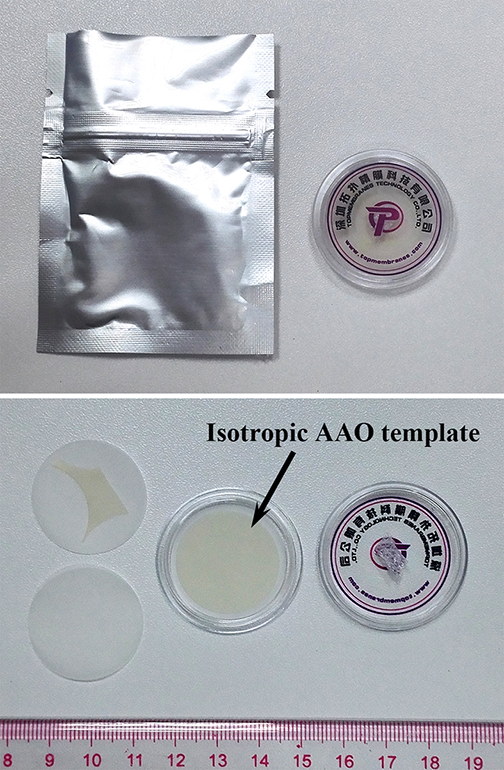

Fig. 1. The structure diagram of isotropic AAO templates.

Fig. 2. Typical SEM images of both sides of isotropic AAO template.

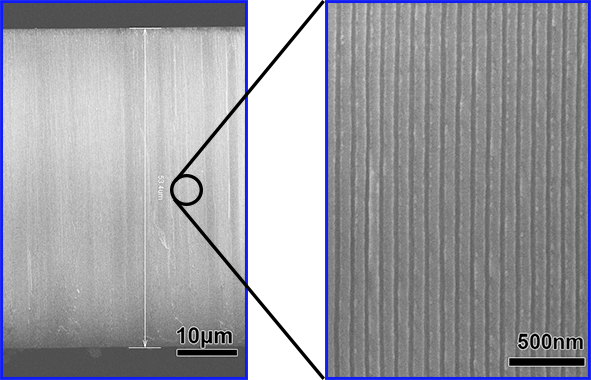

Fig. 3. Typical SEM images of the cross section of isotropic AAO templates.

Isotropic AAO templates are made from AAO on Al substrate. When the thickness is less than 1μm, they are called ultrathin AAO membrane, which often need other materials as supports. When the thickness reaches several tens micron, the structure can be self-supported, and has certain strength and elasticity, which can be used for filtration membrane. Our Isotropic AAO templates have uniform pore diameter from both side of the membrane, and the arrangement is highly ordered. Isotropic AAO template is a great material for making one dimensional nanomaterial via different technique such as electrochemical deposition, hydrothermal process, atomic layer deposition, etc.

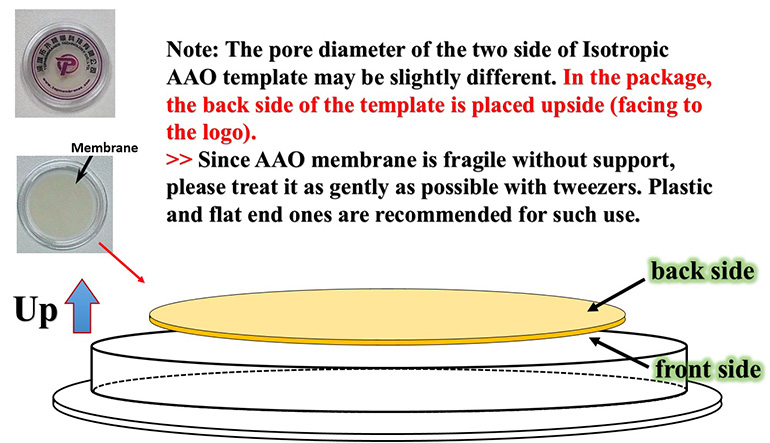

Fig.4 The orientation of the isotropic AAO template in the package.

Since AAO membrane is fragile, treat it with tweezers gently, plastic and flat end ones are suggested.

Note: the front side and back side look the same, if you accidently mix up, contact us for assistant as needed. Normally, have will also receive some small pieces of irregular shape AAO for your imaging use based on request.

Isotropic AAO templates can be removed by 5% phosphate acid at 30℃ slowly, or by 5 wt.% NaOH at room temperature quickly. You can image the structure with either SEM or AFM. Due to the non-conductive nature, the surface need to be sputtered with gold or carbon before SEM test. A fresh cross-section view can be obtain by breaking off the membrane.

Fig. 5. A typical photo of isotropic AAO template.

Fig. 6. Isotropic AAO templates with different sizes

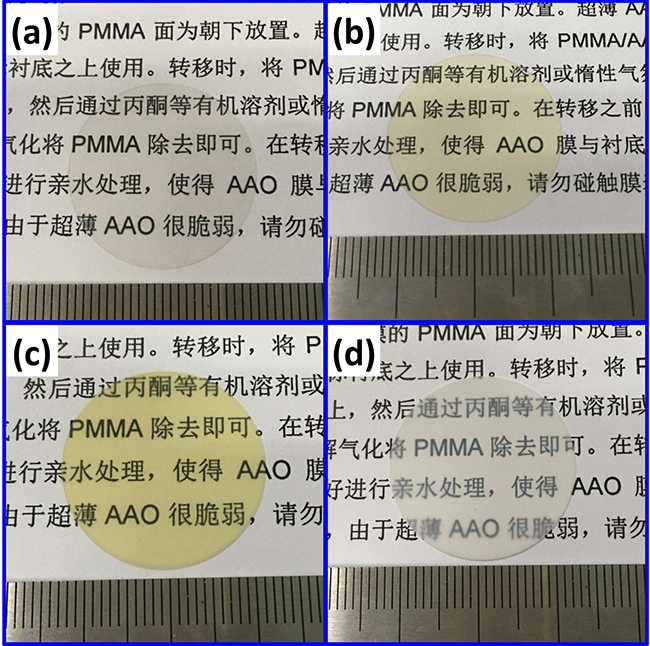

Fig. 7 Transmission of light at short range.The interpore distance is (a) 65nm, (b) 100nm, (c)125nm, (d) 450nm.

About residues:

Isotropic AAO membranes are cut by laser cutting machine from a larger AAO membrane. During cutting, the focused laser beam is directed at the material. It will then either melts, burns, vaporizes away. After cutting, there will be a lot of aluminium oxide fragments scattering around the cutting line. Since the membranes are brittle, air blow was not used during cutting. The residues are the aluminium oxide fragments attached to the membranes during collection. There residues are easy to be removed by ultrasonic cleaning in deionized water for several minutes. Please choose an ultrasonic cleaner with a lower power such as 50~100W.

About the pore diameter difference between front and back pores:

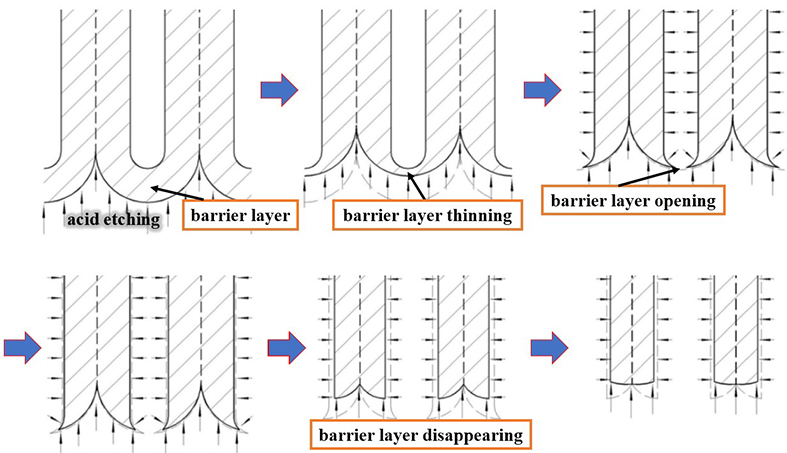

The diameter difference between top and bottom pores is caused mainly by production process and the componential structure of the pores. Originally, the pores of the membranes are not through. There is barrier layer at the bottom of each pore, just like the bottom of a test tube. The barrier layer is removed by acid etching to obtain Isotropic AAO membranes. The etching rates of the top and bottom part of the pore may be different, and it will lead to diameter difference between top and bottom part of the pore. For details, please refer to reference: ACS Appl. Mater. Interfaces 2013, 5, 3441. In this situation, the inner diameter change continuously from top to bottom. In fact, since the length of the pore is about 50000 nm, the diameter difference (several or tens nanometers) is too small.

Fig. 8. Schematic outline of the pore-opening process (cross-sectional view) which shows the etching mechanism. The arrows in the figure show the etching directions, while the lengths of the arrows are proportional to the etching rate. Reference: Small 2010, 6, 695.

Another situation is related to the opening states of the barrier layer. As shown in figure 8, during the acid etching process, the barrier layer firstly open and then disappear. If the etching process is stopped before barrier layer disappearing, the size difference between the top and bottom pore will be larger, and the shape of the most bottom pores is not circle. This situation only happens to these products: DP065-010-50000, DP065-015-50000, DP065-020-50000, DP100-030-50000, DP100-035-50000, and DP125-030-50000. Take DP065-015-50000 (front 30 nm, back 15 nm) as an example, the length of 15 nm size pore is only ~20nm (i.e. the thickness of the barrier layer), and the diameter of other part of the pore varies from about 20 nm (bottom) to about 30 nm (top).

Note: DP450-390S-50000 is not suitable for filtration due to seldom local micron order holes.