Dual-pass AAO templates (thicknesses of tens of microns) generally have a diameter of tens to hundreds of nanometers, while the length of the channels can reach tens of microns. The channels are parallel to each other, and the aperture uniformity is good. Therefore, high aspect ratio and high density metal nanowires can be easily prepared by electrochemical deposition using double-pass AAO as template.

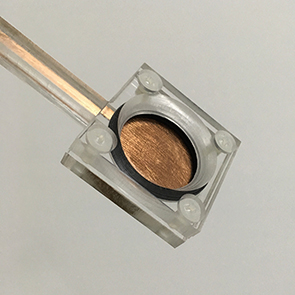

Fig. 1. schematic diagram of fabrication of metal nanowires by electrochemical deposition using double-pass AAO as template

Fig. 1 is a schematic diagram of the fabrication of metal nanowire arrays by electrochemical deposition using double-pass AAO templates. Firstly, magnetron sputtering, electron beam evaporation, thermal evaporation and other methods can be used to prepare a continuous conductive metal layer on the side of double-pass AAO template. The conductive metal layer can be gold, silver, copper, aluminum, nickel, etc. The thickness of conductive metal layer is necessary bigger (for example, the thickness is 500-1000 nm) to completely block and cover the hole of AAO to form a continuous metal layer. Then, appropriate electrochemical deposition solution and deposition conditions (such as current, voltage and time) are used to electrodeposit metal nanowires, which are limited by template holes. During the deposition process, the opposite side of the conductive metal layer of AAO (hereinafter referred to as the front side of AAO) is required to be immersed in the electrochemical deposition solution, and the hole is filled with solution, while the opposite side of the conductive metal layer (the reverse side of the metal layer) must be completely free from contact with the electrochemical deposition solution. In order to meet this requirement and facilitate the installation and disassembly of AAO templates, we have developed a special support for electrochemical deposition of double-pass AAO templates, as shown in Figure 2.

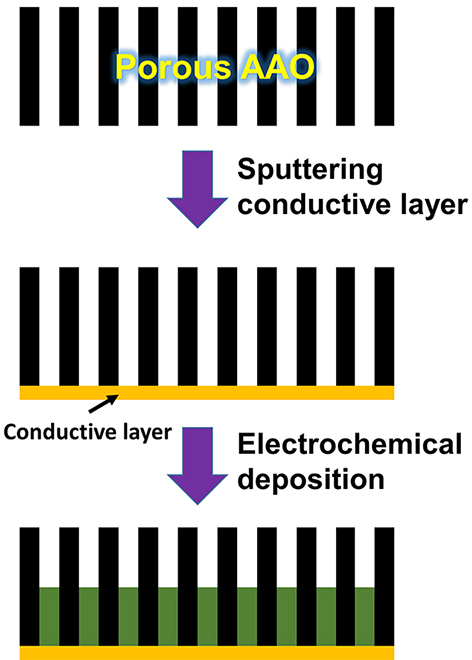

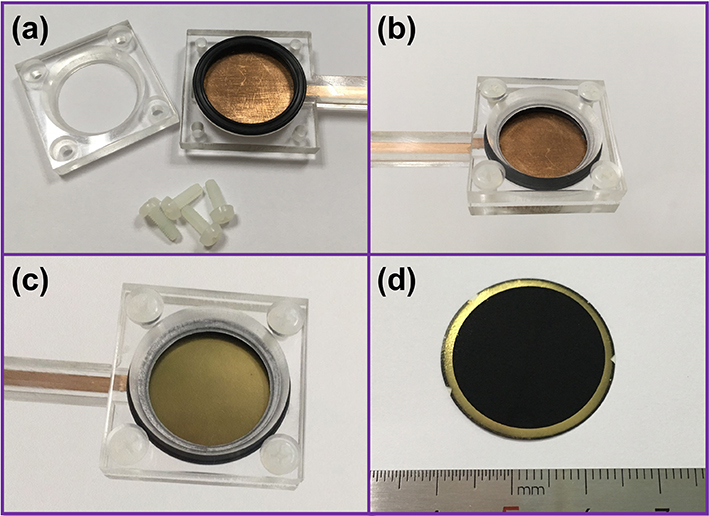

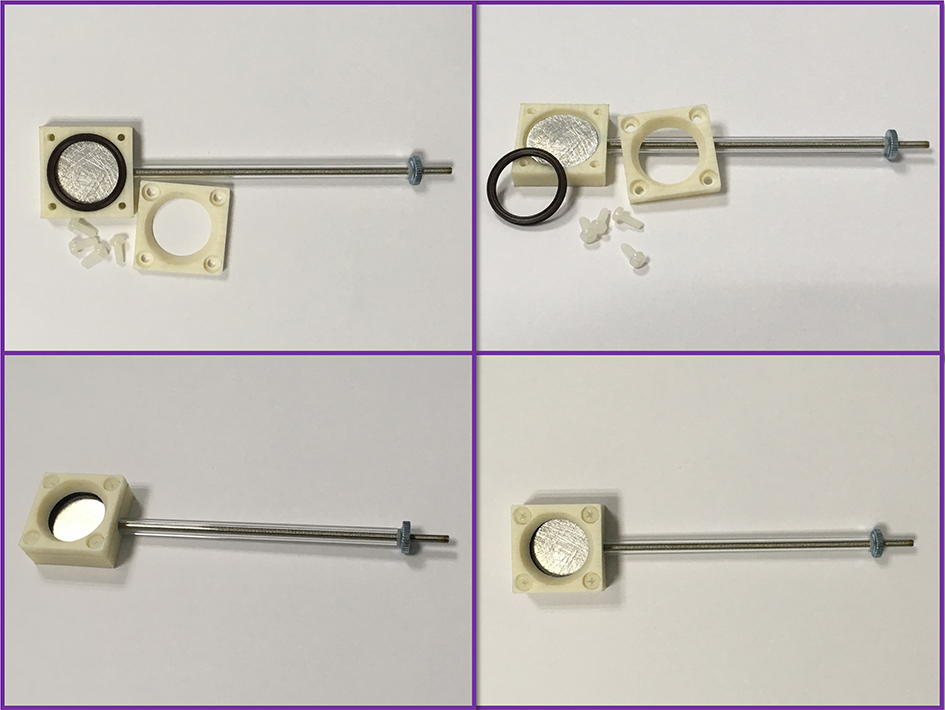

Figure 2. (a, b) Dual-pass AAO template electrochemical deposition stent (acrylic), used for 25mm diameter of dual-pass AAO template. (c) A double-pass AAO template bracket (acrylic) is installed. AAO template has an aperture of about 50 nm, and Au (40 nm) / Al (500 nm) is deposited on the back. (d) Dual-pass AAO templates of nickel were deposited by direct current electrochemical deposition. The effective area diameter is about 21 mm.

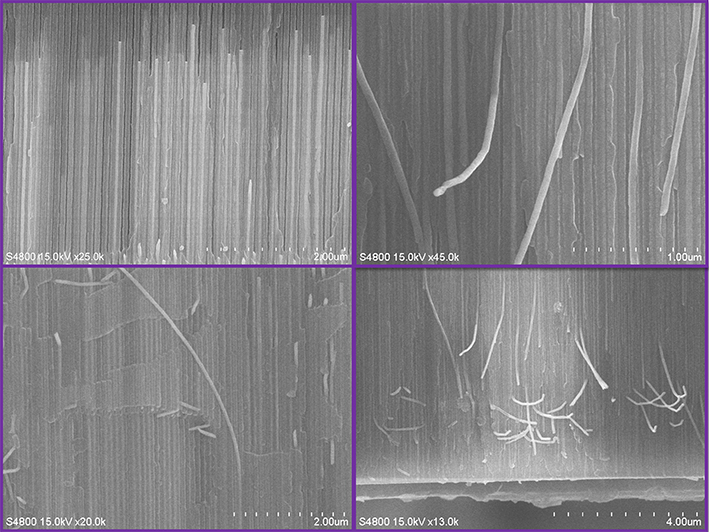

Fig. 3. The double-pass AAO cross section obtained by electrochemical deposition in Fig. 2D shows that the nickel nanowires are clearly visible.

The special bracket for electrochemical deposition mainly uses acrylic and copper. It has good electrical conductivity, mechanical strength and corrosion resistance. The screw and sealing ring are easy to disassemble. Fig. 2 (a, b) is a picture of the bracket used for the double-pass AAO with a diameter of 25 mm. Fig. 2C is a bracket with AAO installed. When the bracket is installed, it is only necessary to ensure that the AAO template is concentric with the copper disc. The cross-section of the bracket handle is square, and the cross-section size is about 5*5mm. Figure 2D shows the double-pass AAO template after nickel deposition. The bracket has compact design, good sealing performance and effective deposition area diameter of 21 mm. Because of the nano-size effect, the Nickel Nanowire region appears black. After the template was broken off, the SEM results showed that the nickel nanowires were clearly visible as shown in Figure 3. When AAO breaks, some nanowires at the fracture surface are pulled out or broken, and the morphology is clearly visible. At present, there are two kinds of special electrochemical deposition scaffolds made of acrylic materials, which are used in the electrochemical deposition experiments of double-pass AAO templates with diameter of 25 mm and 13 mm respectively.

Note: Since acrylic material is soluble in organic solvents, please do not use any organic solvents to clean the device. Deionized water can be used to clean the device.

Figure 4. Electrochemical deposition of nylon brackets (for 25mm double-pass AAO)

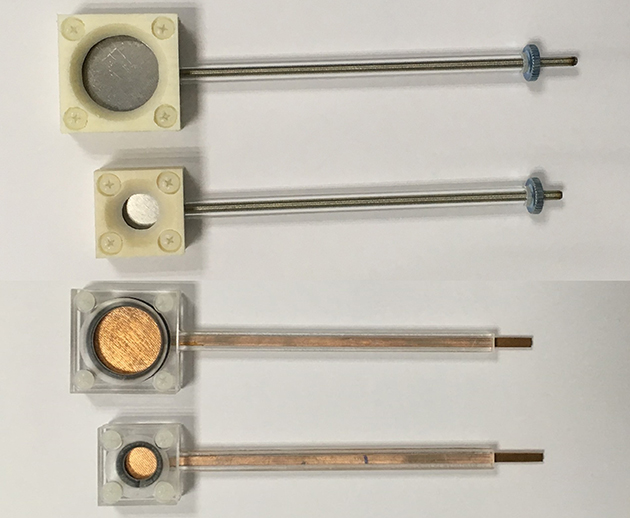

Fig. 5. Four kinds of brackets, top-down nylon bracket (25mm), nylon bracket (13mm), acrylic bracket (25mm), acrylic bracket (13mm)

Because the solvents used in electrolyte of electrochemical deposition are sometimes organic solvents, and acrylic scaffolds may be corroded by organic solvents, we designed nylon scaffolds to solve this problem, as shown in Figure 4. The inner part of the handle is stainless steel screw, the outer part is quartz tube, and the outer diameter of quartz tube is 6mm. The sealing ring is fluorine rubber ring, corrosion resistant. AAO gasket is made of aluminium. The resistance from the aluminium gasket to the top of the stainless steel rod is about 0.1 ohms. Photographs of the four stents are shown in Fig. 5. No matter which kind of bracket, due to the left and right of the sealing ring, it can ensure good sealing. When electrochemical deposition, the electrodeposition solution will not touch the internal conductive metal. It should be noted that before electrochemical deposition, a thick conductive metal layer must be evaporated on the back of AAO. The thickness must ensure that all the holes of AAO are blocked (which is very important), and a continuous conductive metal film can be formed. For example, the thickness of AAO is about 500-1000 nm, which can be gold, silver, aluminium, nickel, titanium, copper and so on.