The ideal microporous membranes is supposed to have uniform pores, which are critical to the precise control of industry processes, such as filtration, separation, purification and material preparation. This kind of membrane has wide applications in the fields of chemical industry, medicine, biopharmaceuticals, quality control and water treatment. However, the current techniques of membrane fabrication (e.g. track etching) and synthesis (e.g. phase inversion and interfacial polymerization) have disadvantages of complexity, multiple-procedure, and uncertainty. All of these methods lack of precise control of pore size, leading to inefficient membranes in various applications.

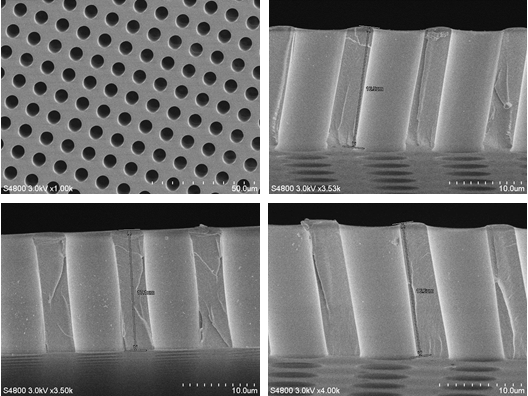

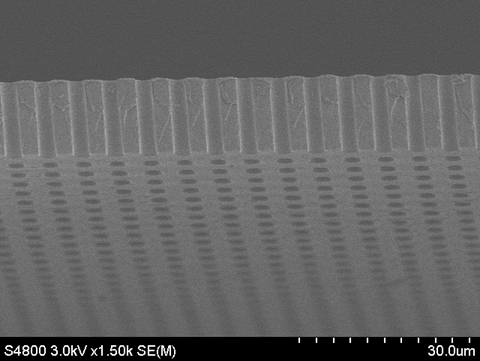

To realize accurate control of homogeneous membrane modality, we have developed a special microfabrication technique. With this original method, we can fabricate the homogeneous and porous organic membrane, which features straight, uniform and smooth micropores in a regular array arrangement. The standard deviation (SD) of the pore diameter is less than 3% and the porosity is up to 50%. Compared with the microporous membranes in the market, our product has superior performances in pore size uniformity, porosity, pore-open ratio, water flux, retention rate, chemical and physical stability, etc.

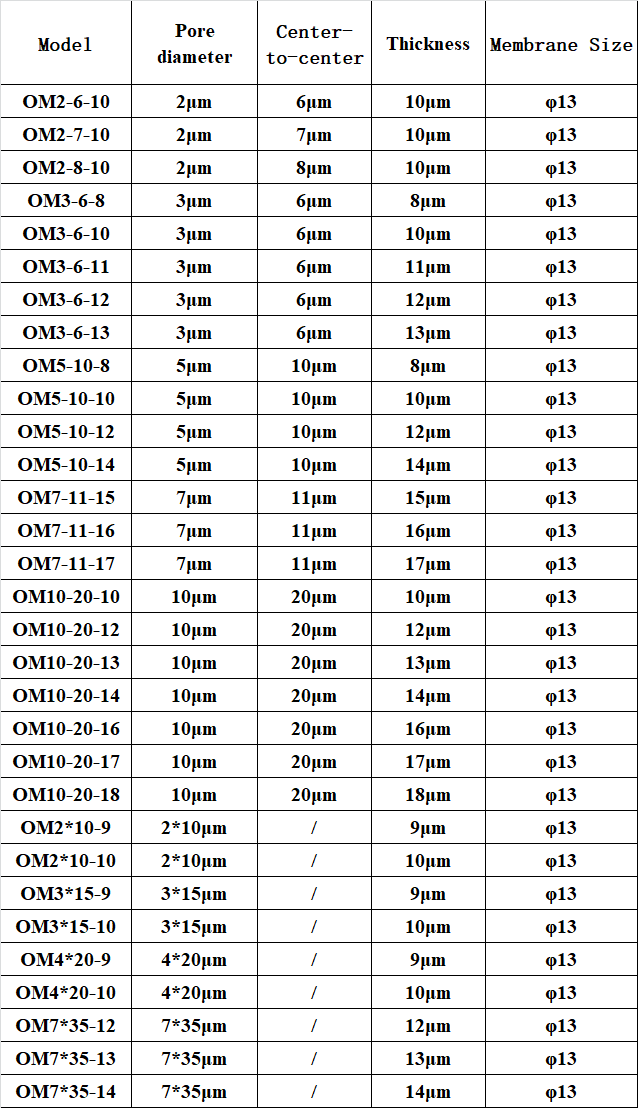

Membrane customization is provided in terms of pore size, shape, arrangement and thickness according to specific requirements of our customers. In the nature of our fabrication, our customization is economical, and thus suitable for experimental test in research. The final design can be also easily upgraded to mass production for future commercialization.

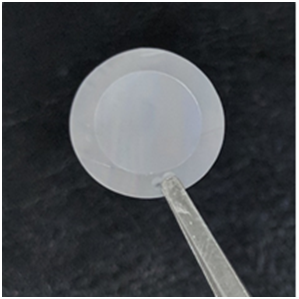

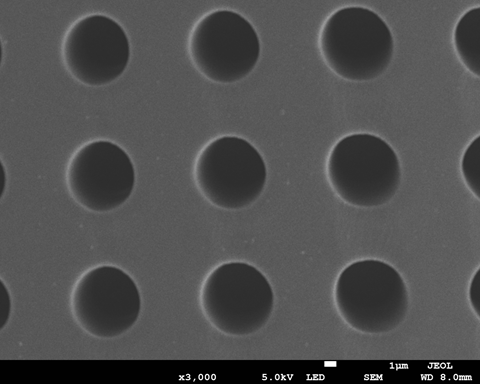

Figure 1. Micropore organic membrane (13mm)

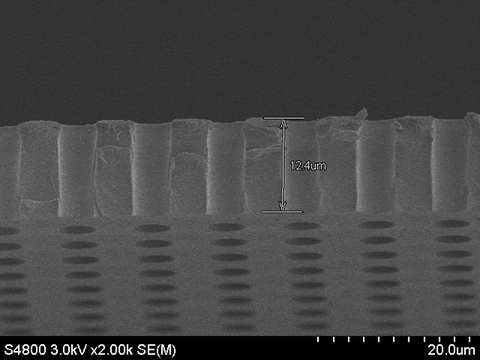

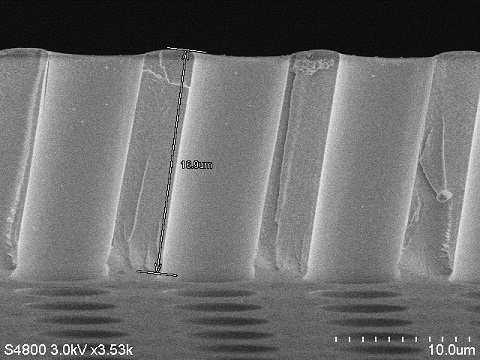

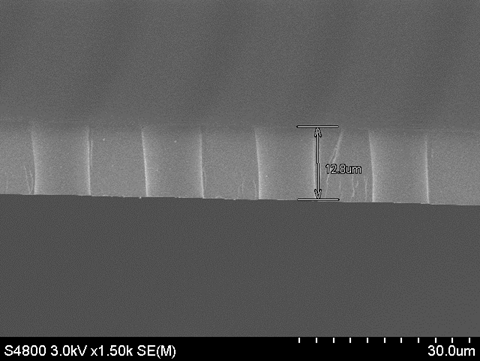

Figure 2. The SEM sectional view of OM3-6-14

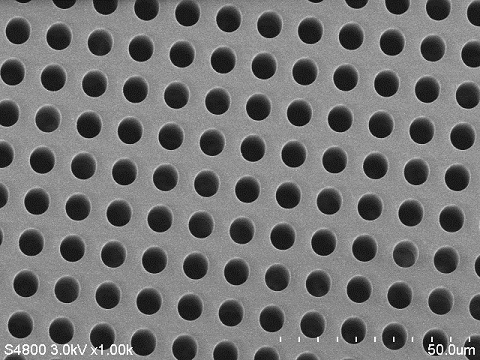

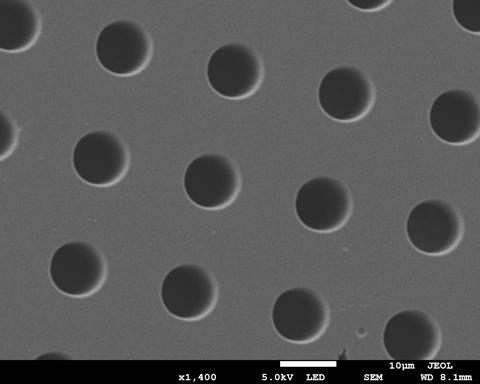

Figure 3. The SEM front view of OM5-10-14

Figure 4. The SEM sectional view of OM5-10-14

Figure 5. The SEM front view of OM7-11-17

Figure 6. The SEM sectional view of OM7-11-17

Figure 7. The SEM front view of OM10-20-14

Figure 8. The SEM sectional view of OM10-20-14

Figure 9. The SEM front view of OM2*10-10

Figure 10. The SEM front view of OM3*15-10

Figure 11. The SEM front view of OM4*20-10

Figure 12. The SEM front view of OM2-6-10

Figure 13. The SEM front view of OM2-7-10

Figure 14. The SEM front view of OM7*35-12

*The above are micropore membranes with pore diameter of 2, 3, 5, 7, 10 μm. If you need customization, please contact our customer service.

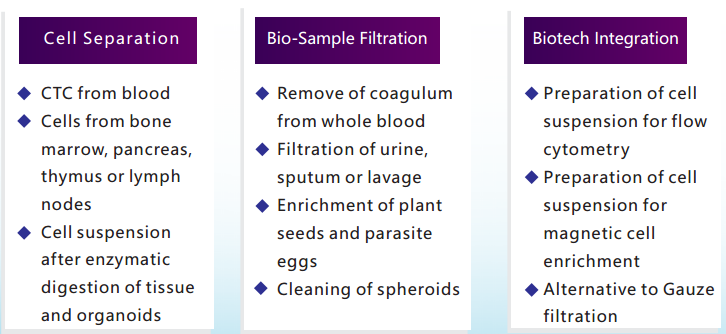

The potential applications of this kind of homogeneous micropore membranes include the filtration and separation of various micro-particles, e.g. biological sample filtration, cell strainer, cell filtration, cell separation and cell enrichment, separation and capture of cells. The packaged membrane is 13mm in diameter and can fit a standard syringe filter. It is attached to a support ring for easy gripping.