Persistent drivers of water stress, such as climate change and urban population growth, are motivating interest in potable reuse systems. For extreme environments (e.g., in space) or in locations with extenuating circumstances (e.g., military forward operating bases), water treatment systems that are compact and easily deployable are required. Furthermore, at forward operating bases, significant risk is associated with convoys supplying potable water and fuel to the base as well as convoys taking wastewater away; thus, a system that can reclaim wastewater for potable reuse with a low electrical energy requirement is of critical importance. The development of potable reuse systems tailored to meet these unique challenges has direct implications for development of municipal potable reuse systems.

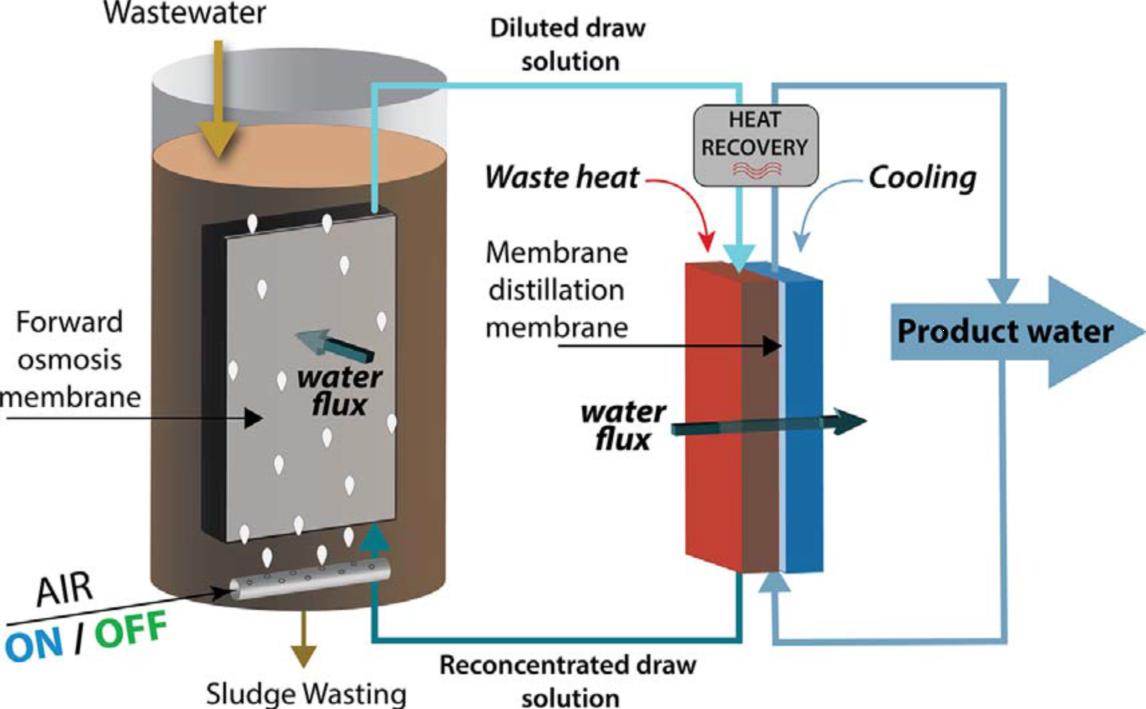

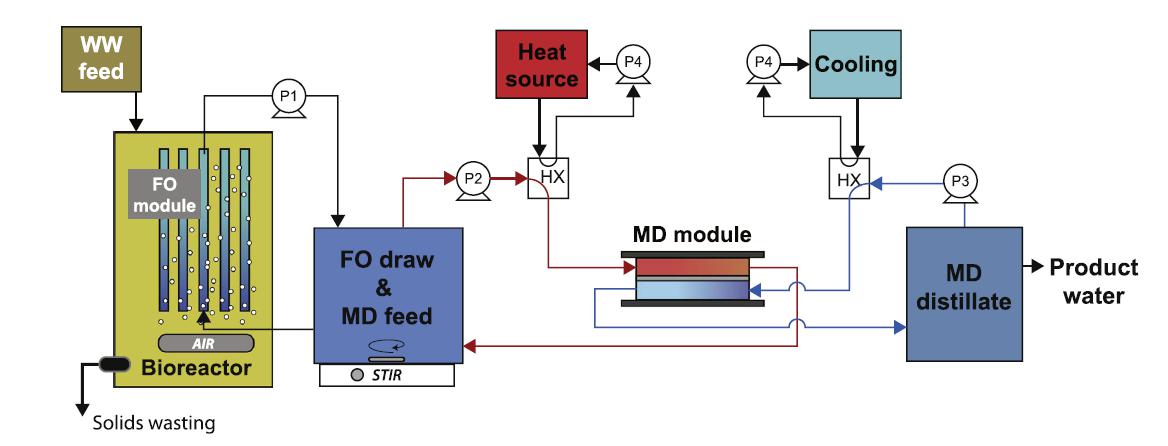

For reuse applications, membrane bioreactors (MBRs) with microfiltration (MF) or ultrafiltration (UF) membranes submerged in a biological reactor have emerged as an efficient wastewater treatment process to provide high-quality filtrate to a subsequent reverse osmosis (RO) process followed by advanced oxidation. More recently, osmotic membrane bioreactors (OMBRs) with forward osmosis (FO) membranes submerged in the bioreactor are being investigated as lowfouling alternatives to conventional MBRs. If the opportunity exists to reconcentrate the FO draw solution with waste-heat driven membrane distillation (MD), then the OMBR-MD system can provide high quality product water with a low electrical energy requirement. In an aerobic OMBR-MD system, wastewater is fed into a bioreactor that is aerated to supply oxygen to the biomass and scour the membrane. Through osmosis, water diffuses from the bioreactor, across a semi-permeable FO membrane, into the draw solution. The FO membrane acts as a barrier to solute transport and provides high rejection of contaminants in the wastewater stream. The diluted draw solution is sent to MD for reconcentration and generation of product water.

Fig. 1. Graphical representation of an integrated OMBR-MD system in direct configuration. FO and MD processes work simultaneously from one tank; the FO draw solution tank is also the MD feed solution tank.