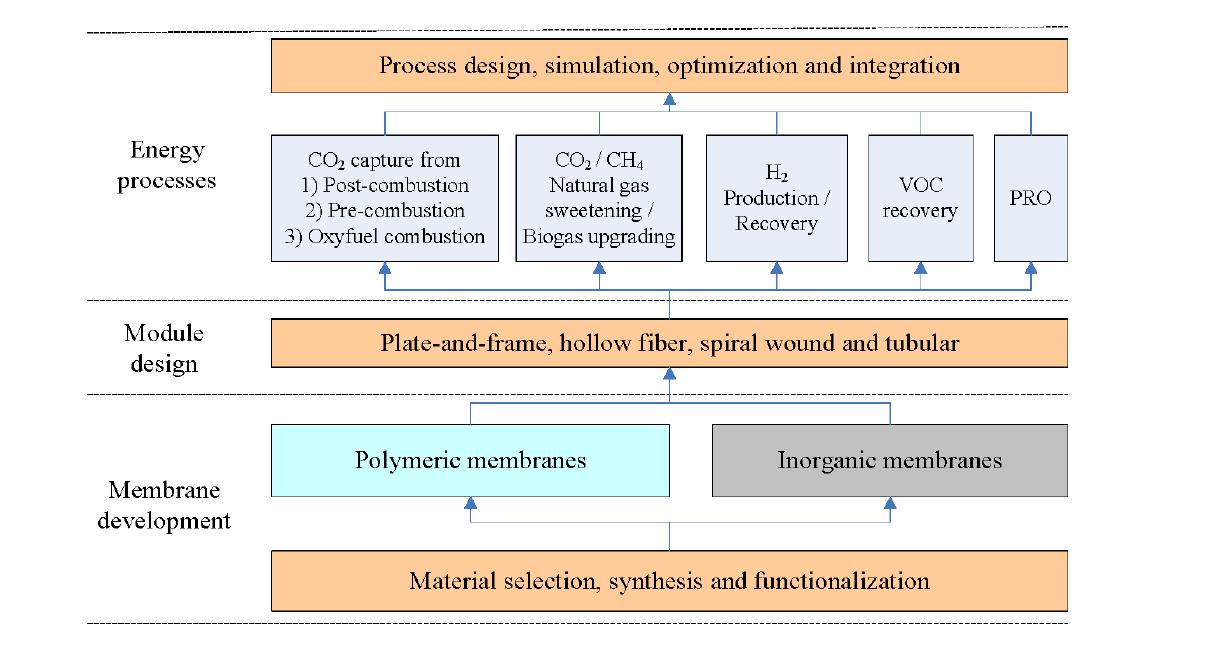

Membranes are becoming a competitive technology compared to the conventional separation unit operations, e.g., cryogenic distillation, chemical and physical absorption. Membrane gas separation has played an important role in various environmental and energy processes, such as CO2 capture, VOC recovery, natural gas sweetening, biogas upgrading, hydrogen production during the last two decades, and can potentially compete with some traditional separation methods in terms of energy requirements and economic costs. Different types of membrane materials such as common polymers, microporous organic polymers (MOPs), fixed-site-carrier (FSC) membranes, mixed matrix membranes (MMMs), carbon molecular sieve membranes (CMSMs), as well as inorganic (ceramic, metallic, zeolites) membranes, have been reported to be used in various gas separation processes. Moreover, proton exchange membranes (PEM) electrolyzers have been used for H2 production. Recently, pressure retarded osmosis (PRO) technology for power generation (based on knowledge about reverse osmosis (RO)) or forward osmosis (FO) membranes show a great potential for sustainable energy production. Figure 1 shows an overview of membrane systems for environmentally friendly energy processes from materials to applications. Choosing a suitable membrane material for a specific application will mainly depend on feed gas composition, process conditions as well the separation requirements. Bernardo et al.conducted a review on the status of membrane materials (typically focused on O2/N2, CO2/N2 and CO2/CH4 membranes), relevant industrial applications, and future opportunities. Their contribution addressed the state-of-the-art materials and the major efforts in the development of the membrane gas separation field.

Figure 1. An overview of membrane systems used in different energy processes.

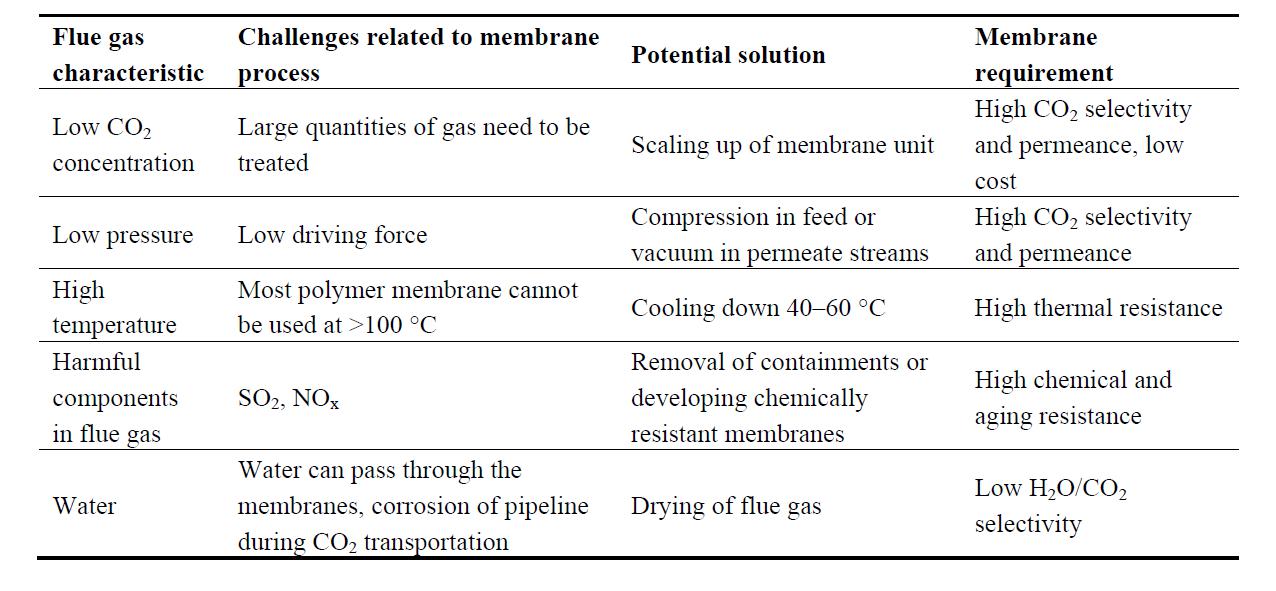

Many research activities on the investigations of different membranes for CO2 capture have been conducted, some examples are given in. He et al. investigated the application of hollow fiber carbon membranes for CO2 capture from flue gas. They reported a capital cost of 100 $/tonne CO2 avoided using carbon membrane, which is still higher than traditional chemical absorption method of MEA (59 $/tonne CO2 avoided reported by Rao and Rubin), but the referred carbon membranes had a clear potential for further optimization. Merkel et al. [46] reported that a membrane with a CO2/N2 selectivity above 50 and a 4000 GPU permeance (1 GPU = 2.736 × 10−3 m3 (STP)/(m2 h bar)) could offer a capture cost below 15 $/tonne CO2, which is lower than the US Department of Energy’s (DOE) target of 20 $/tonne CO2. Their innovative process solution to the CO2 capture is also contributing strongly to their conclusion where they also pointed out that improving membrane permeance is more important than increasing selectivity (given selectivity is >30) in order to further reduce the membrane unit’s cost. Hussain et al. conducted a feasibility analysis by HYSYS integrated with an in-house membrane program (ChemBrane, developed by Grainger) to investigate the influence of process parameters on energy demands and cost using a novel CO2-selective FSC membrane. Their results indicated that a membrane system using high performance FSC membranes was feasible for CO2 capture, even at a low CO2 concentration (~10%) in a flue gas, compared to amine absorption in terms of energy requirement, and it was also possible to achieve more than 90% CO2 recovery and >95% CO2 purity in permeate stream. In any case, this environmentally friendly technology with improved membrane performance could promote membrane systems as a promising candidate for CO2 capture from flue gas in post-combustion process if all the challenges (shown in Table 1) can be well addressed.

Table 1. Challenges related to standard membrane systems used in post combustion process.

Liquid membranes have also been investigated for CO2 separation, and most of these works use non-volatile liquids of room temperature ionic liquids (RTILs) as the carriers to transport CO2. A review on the development of liquid membranes for gas/vapor separation has been conducted by Krull et al.. They pointed out that the use of ionic liquids could improve the liquid membrane stability. However, ionic liquids are still in a minority and not commercially available. Another challenge of liquid membranes is the lack of long-term stability when faced with CO2 capture in industrial application. Membrane contactors, which combine gas separation membranes and solvents, offer a unique way to perform gas-liquid absorption and provide high operational flexibility. There has been strong interest focused on the improvement of membrane contactor efficiency for CO2 capture. Yeon et al. reported the use of a polyvinylidene difluoride (PVDF) hollow fiber membrane contactor for absorption and a stripper column as desorber for CO2/N2 separation, which presented a higher CO2 removal efficiency than the conventional absorption column. Feron et al. have investigated the potential application of CO2 capture from flue gas using a membrane contactor composed of porous polypropylene hollow fiber membranes and a dedicated absorption liquid (CORAL). Their results indicated that a membrane contactor could be an interesting candidate for CO2 capture from flue gas in post-combustion power plants. In conclusion, for post-combustion CO2 capture, the indications are that the only membranes which will have a potential of being economically viable will need to be polymers with high flux, and moderate to high selectivity (CO2/N2) and can tolerate impurities such as SO2, NOx and H2O. The new membrane contactors containing stable carriers are also promising candidates. Innovative energy-saving process solutions will likewise help to promote membranes for this application.

Membrane technology shows strong potentials in various energy processes including CO2 capturefrom flue gas in power plants, natural gas sweetening, biogas upgrading, H2 recovery, VOC recovery as well as power PRO generation. However, for any kind of suitable application, a high performance membrane material is required, while taking into consideration some key parameters such as transport properties, durability and mechanical strength. The following aspects can be further investigated to achieve a high efficiency membrane process:

● Membrane transport properties (pemeance and selectivity)

● Mechanical strength, chemical and thermal stability under a specific operating condition

● Membrane durability over the long term by being exposed to real process conditions

● Membrane module design

● Process design, simulation, optimization and integration

Three specific parameters—environmental, economic and social indicators—are usually employed to compare membrane systems with the other traditional unit operations towards sustainability, and evaluate which technique could be more suitable for a specific application. However, for any specific application, process conditions need to be carefully considered before making a decision. Nevertheless, the prediction is that membrane systems, which require no or very little chemicals compared to standard unit operations, in addition to being easy to scale up and having low energy consumption, will be an environmentally friendly technology for application in energy processes in the future.