An Australian research team headed by two young Chinese and Korean doctors has developed a method to produce graphene, a nanomaterial 200 times harder than steel, from soybean oil eaten in daily life, which greatly reduces commercial production of graphene, according to the Sing Tao Daily. The cost of future materials.

One of the co-authors of the study, Zhao Junhan, a Chinese-American from the Australian Academy of Sciences (CSIRO), said that this way of making graphene could produce the nanomaterials faster and cheaper than other methods developed by scientists around the world.

The research results were published in Nature Communications magazine recently.

Dr. Zhao Junhan said the method could use low-cost raw materials such as vegetable oils, such as soybean oil heated in a tubular furnace for about 30 minutes. Soybean oil would break down into carbon units on nickel foil, then quickly cool and form graphene films on the surface of the foil.

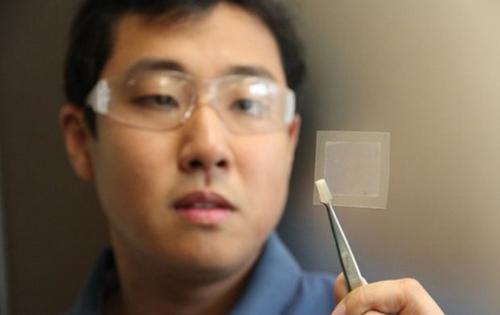

Another co-author of the study, Dr. Dong Han Seo, a Korean-born doctor, showed the media that graphene films were made in new ways.

Display graphene films made from soybean oil (from Australia's Sing Tao Daily)

In 2004, scientists at the University of Manchester in the United Kingdom first discovered graphene, the world's thinnest, strongest and most conductive nanomaterial, which won the Nobel Prize in 2010.

Graphene is the "king of new materials" with only one atomic layer thickness. It can be used in many aspects such as computers, solar panels, sensors and medical equipment. Scientists predict that graphene is likely to unleash a revolutionary new technology and industry sweeping the world.

But so far, scientists in various countries have been making graphene very expensive. Many methods of making this material require high vacuum and heat conditions and expensive raw materials, which hinder the commercial production of graphene on a large scale.

This innovative breakthrough by Australian scientists could significantly reduce production costs and further expand the commercial use of graphene.

According to experts, the use of soybean oil to produce graphene, the use of low-cost renewable resources, the commercial production of graphene will be further, is bound to cause global concern.

The Australian Academy of Sciences is working on graphene films to improve current water filtration membranes and to replace expensive metals such as gold and platinum in solar photovoltaic panels, Dr. Zhao Junhan said.