According to the X-MOL News of October 23, 2016, the earliest discussion of Janus particles may be traced back to the Nobel Prize speech by P.G. de Gennes (of course, the earliest article on Janus particles was earlier). Janus is the name of two-faced gods in ancient Roman mythology. It is said that Janus has two faces, one facing the past and the other facing the future. In the field of chemistry, it is used to describe materials with asymmetric structures, especially those with opposite structures or properties. Janus particles have also become one of the earliest Janus materials.

When the concept of Janus was introduced to two-dimensional materials, Janus interfacial materials became a new focus for researchers, such as Janus films.

Early studies on Janus membranes focused on their unique directional permeation phenomena. With the in-depth understanding of Janus membranes, related studies are gradually turning to practical applications, such as oil-water separation, enzyme membrane reactor, bubbler, membrane distillation and so on.

Professors Sam Kyu Kwak and Sam-Young Lee of the Ulsan National Institute of Science and Technology (UNIST) in South Korea applied Janus-structured battery separators to lithium-ion batteries. The papers were published in Advanced Functional Materials. (Janus-Faced, Dual-Conductive/Chemically Active Battery Separator Membranes.Adv.Funct.Mater., 2016, DOI: 10.1002/adfm.201602734).

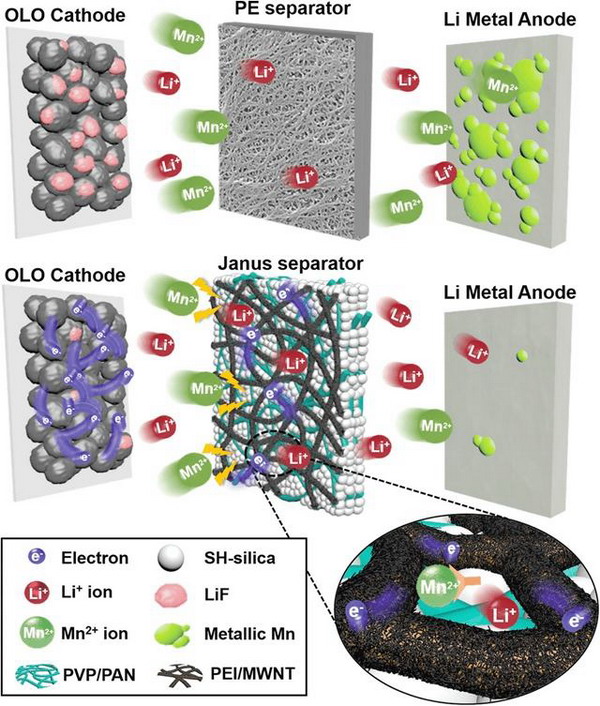

In lithium-ion batteries, battery diaphragms play two main roles: one is to isolate positive and negative electrodes to prevent short circuit; the other is to provide ion channels. But in this work, the researchers put their concerns on two other issues. On the one hand, the dissolution of heavy metal ions (such as Mn2+, Ni2+, Co2+) in lithium metal oxides in cathode during repeated charging and discharging will cause the change of cathode structure, and the migration of heavy metal ions to anode will lead to the rapid degradation of battery capacity during cyclic charging and discharging, especially at high temperature. It is. On the other hand, although the traditional idea is that the battery diaphragm should be completely insulated, recent studies on lithium-sulfur batteries have shown that if the part of the battery diaphragm close to the electrode is a thin conductive layer, it may be conducive to conducting the electrons of the electrode.

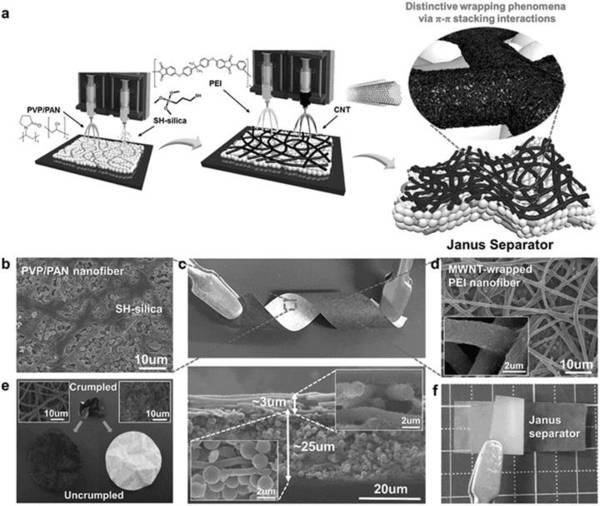

Based on the above background, researchers have fabricated cell separators with Janus structure using synchronous electrospinning/electrospray technology. The cell separator consists of two parts, one is synchronously electrospun polyvinylpyrrolidone/polyacrylonitrile (PVP/PAN) nanofibers and electrosprayed mercapto silica particles (25 microns thick), the other is electrospun polyetherimide (PEI) and electrosprayed carbon nanotubes (3 microns thick). After the preparation, they also increased the adhesion between the two layers through the roller hot pressing technology. The sulfhydryl group on the surface of SiO2/PVP/PAN layer can effectively capture the heavy metal ions in the electrolyte, while the PEI/CNT layer has good conductivity (conductivity is about 4.93S/cm), which can improve the electronic conductivity of the cathode surface.

The experimental results are obvious. Compared with the traditional polyolefin battery separator, the performance of the Janus membrane has been significantly improved in various aspects. Especially after solving the deposition problem of heavy metal ions on the anode surface, the decrease of battery capacity in multiple cycles has been effectively suppressed.

Finally, summarize briefly. An important design idea of Janus membrane is to solve different problems in the application process through two layers of different properties of the membrane. This idea is fully embodied in this paper. In future research, this potential of Janus membrane can also be applied to various branches of the environment, energy, medical and other fields.