MBR membrane bioreactor is a new and efficient wastewater treatment process, which greatly improves the solid-liquid separation capacity. The treated water quality standards exceed the national first-class A. Then, what environmental protection devices and components are included in the MBR membrane bioreactor? What are its technological characteristics, advantages, uses and scope of application?

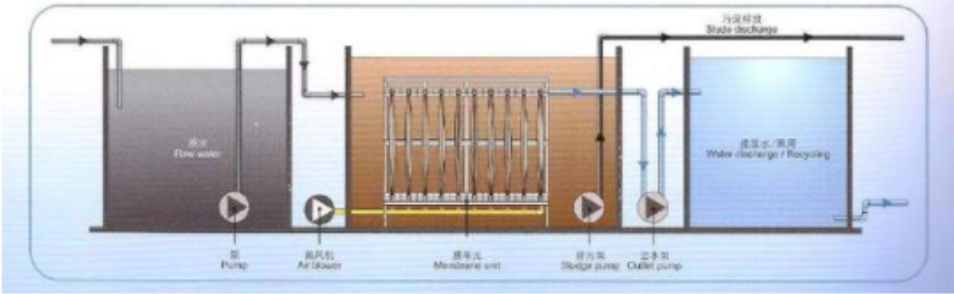

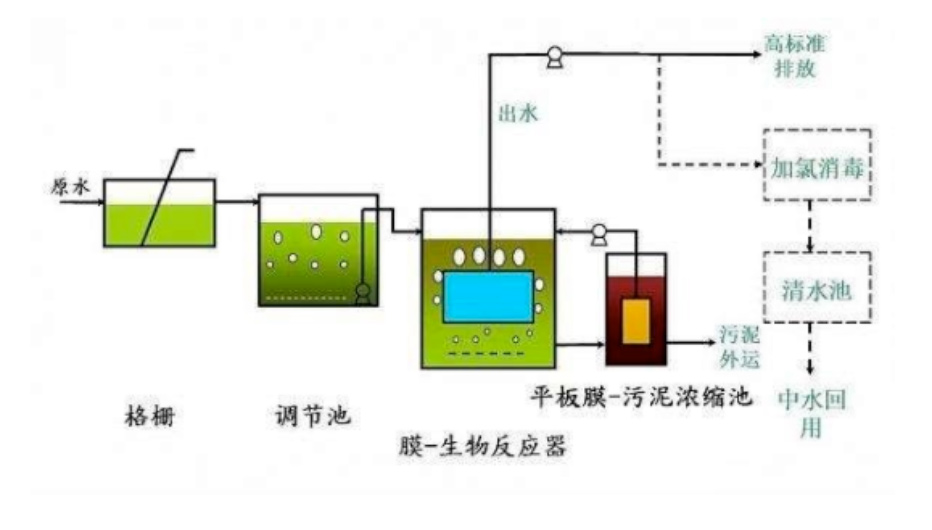

MBR membrane bioreactor (MBR MBR MBR MBR) is a new type of high-efficiency wastewater treatment process which combines high-efficiency membrane separation technology with traditional activated sludge process. MBR flat membrane module with unique structure is placed in the aeration tank. After aerobic aeration and biological treatment, the water is pumped through filter membrane filtration. MBR sewage treatment is very different from traditional sewage treatment methods. Membrane separation device is used to replace the secondary sedimentation tank and three-stage treatment process in traditional process. Thus, high quality effluent is obtained, and the problem that the effluent quality of sewage treatment by traditional environmental protection equipment can not meet the requirements of reclaimed water reuse is solved. MBR water after sewage treatment can be directly used as municipal water or further treated as various industrial water.

Because the existence of MBR membrane greatly improves the solid-liquid separation ability of the system, the effluent quality and volumetric load of MBR membrane bioreactor have been greatly improved. The treated water has a high standard of water quality (exceeding the national first-class A standard). After disinfection, high quality reclaimed water with high water quality and biological safety is finally formed. It can be used as a new source of water directly. Due to membrane filtration, microorganisms are completely intercepted in MBR membrane bioreactor, and the complete separation of hydraulic retention time and activated sludge sludge sludge age is achieved. The sludge bulking problem in traditional activated sludge process is eliminated. MBR membrane bioreactor has the advantages of high removal efficiency of pollutants, strong nitrification ability, simultaneous nitrification, denitrification and denitrification, stable effluent quality, low excess sludge yield, compact equipment, less floor space (only 1/3-1/2 of the traditional process), convenient increment, high degree of automation, simple operation and so on. Point.

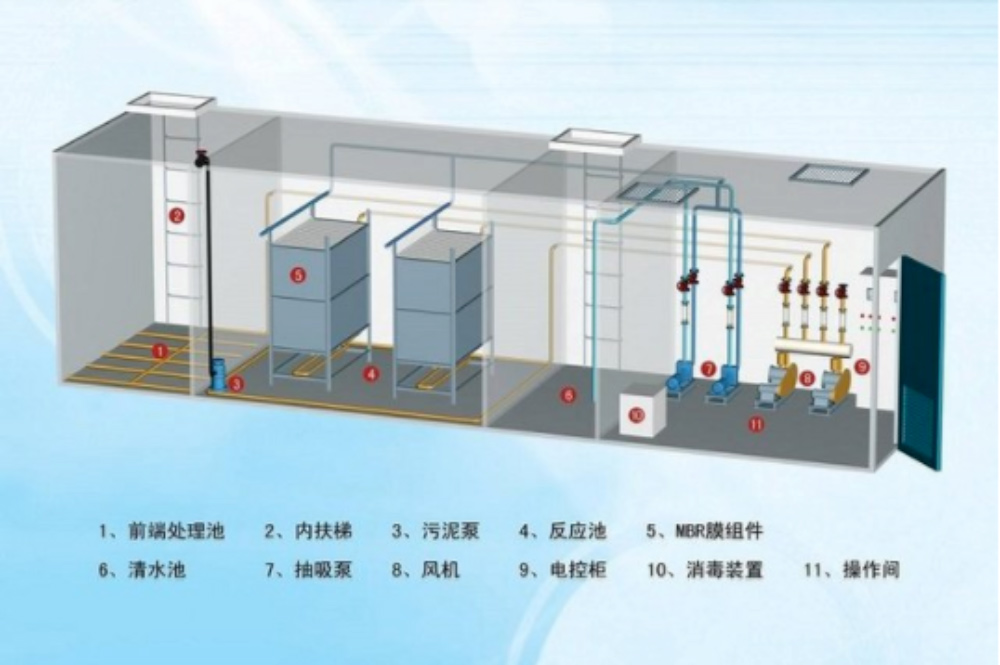

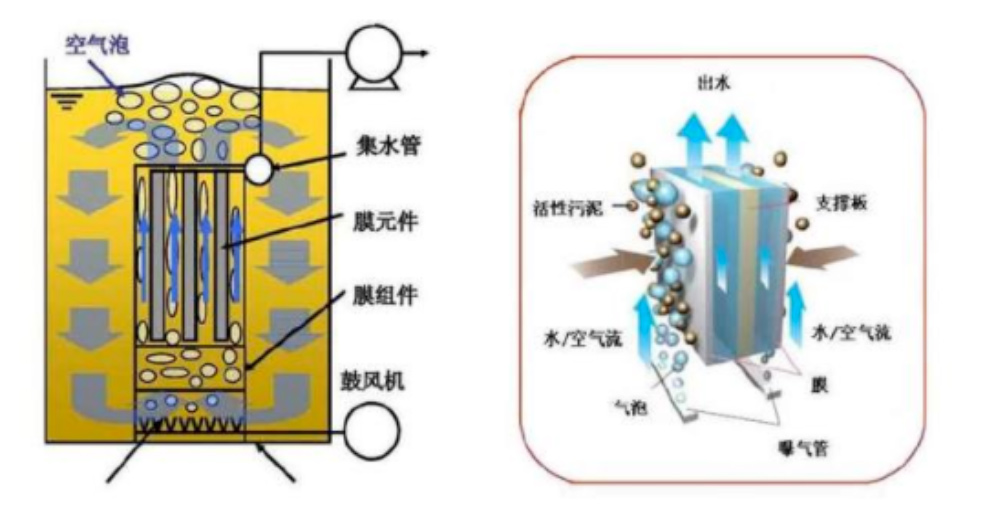

MBR membrane bioreactor module series has the advantages of compact structure, beautiful appearance, small floor area, low operating cost, stability and reliability, high degree of automation, easy maintenance and operation. The quality of MBR effluent is better than that of reclaimed water. With the unique MBR flat film technology, it overcomes many shortcomings of hollow fiber membrane and is an advanced sewage treatment equipment in the world. The series of MBR membrane modules have formed a standardized series of products. Each module consists of 50-150 standard flat sheet diaphragms. It can also be designed individually to meet the needs of users.

Use:

Upgrading and transformation of existing sewage treatment plants and water works

New municipal sewage treatment plant and waterworks

Treatment of high concentration organic wastewater

Pretreatment of pure water production

Reclaimed water reuse

Scope of application:

Municipal life

Hospital Wastewater

Washing wastewater

Industrial wastewater

Food wastewater

Main advantages:

MBR membrane bioreactor has the following outstanding advantages in MBR sewage treatment and MBR reclaimed water reuse engineering.

1. MBR membrane bioreactor has high pollutant removal efficiency and good effluent quality.

2. MBR membrane bioreactor has high sludge concentration, large volume loading and small footprint.

3. MBR membrane bioreactor is conducive to the interception of microorganisms with slow proliferation or high efficiency, and improves the nitrification efficiency and the treatment ability of refractory organic matter.

4. The production of excess sludge from MBR membrane bioreactor is low.

5. MBR membrane bioreactor is easy to realize automatic control and convenient operation and management.

6. After treatment, the SS and turbidity of the discharged water are close to zero and can be reused.

MBR reclaimed water treatment equipment is suitable for the treatment of small-scale decentralized water pollution, such as: government agencies, scenic spots, residential areas, new rural construction, schools and so on. The utility model has the advantages of small floor area, high efficiency and energy saving, intelligent control, low energy consumption, stable effluent quality, and unattended care.

Technical characteristics

1, membrane bioreactor technology characteristics:

Membrane bioreactor (MBR) is a new type of wastewater biochemical treatment system. It is the product of the combination of traditional biological treatment technology and membrane separation technology. To put it simply, this hollow fiber membrane module is directly placed in the aeration tank for slurry separation. The selective permeability of membrane is used to realize biological enrichment in the aeration tank, which greatly improves the efficiency of biological treatment. The wastewater after biological treatment is separated by membrane to obtain clean reuse water. It is an important technology to protect the water environment and realize the reuse of sewage.

For the new sewage treatment plant, its area is smaller than the traditional process, about 1/3-1/5, can effectively save land; if the existing sewage treatment plant is transformed, can not increase the premise of the structure, greatly improve the treatment capacity;

To achieve bioaccumulation and co metabolism. Microorganisms such as nitrifying bacteria with long generation cycle in sewage can be effectively intercepted and ammonia nitrogen can be effectively degraded. The co-metabolism of a large number of microorganisms can degrade some organics which are difficult to biodegrade.

Because of the interception effect of the membrane, the biological concentration in the biological phase is very high, which can reach more than 10 000 mg/l, so the ability to resist shock loading is very strong.

Because the bio-treated sludge is separated by membrane technology, there is no need to worry about the filamentous bacteria reproduction, sludge floating, loss and other issues in traditional biological treatment technology, the operation is more simple and convenient.

The effluent quality is excellent and stable.

2. Characteristics of UE-MBR membrane bioreactor technology:

Balanced traffic assignment and control system

Air cleaning and guiding device for diaphragm assembly

Convenient and flexible assembly membrane rack design

Independent biological treatment and membrane area design

Online backwash

Chemical cleaning

3. Characteristics of petrochemical sewage:

It contains a large number of toxic compounds (such as oils, phenols, amines, ethers, cyanides and sulphur compounds).

Containing refractory pollutants such as toluene, xylene olefins, alkanes, polycyclic aromatic hydrocarbons, monocyclic aromatic hydrocarbons and their derivatives, etc.

Because of the poor biodegradability, the traditional biochemical process for treating the wastewater has the disadvantages of poor removal efficiency of ammonia nitrogen and oil, and weak shock load resistance.

There is a certain degree of impact load, which is very unfavorable for the stable operation of the biochemical treatment system.

Through the practical application of membrane bioreactor technology in petrochemical wastewater treatment and reuse, it can be clearly seen that the membrane bioreactor technology (taking UE-MBR technology as an example) can effectively degrade the petrochemical wastewater after effectively solving the technical problems of high concentration biological activity stability, membrane flux maintenance and amplification effect. The organic pollutants and other nutrients in the system have the characteristics of strong shock resistance, high biological treatment efficiency and small area. The effluent can be reused directly in the cooling circulating water system or in the pretreatment inlet of advanced treatment such as sodium filtration or reverse osmosis. It is very important for enterprises to reduce pollutant discharge, improve the reuse rate of sewage and ensure the safety of the reuse system. It is also good for other industrial sewage treatment and reuse with similar characteristics. It is worth studying and promoting.

To some extent, membrane bioreactor technology originated from the traditional sewage biological treatment process, but it has reached a height that traditional sewage biological treatment technology can not reach. Therefore, we have reason to believe that membrane bioreactor technology can be competent or accomplished better as long as the sewage can be treated by traditional biological treatment technology. Of course, membrane bioreactor technology is not omnipotent, in its use process, it must be targeted at the traditional sewage pretreatment, and other treatment methods for organic combination, in order to maximize its effectiveness, the realization of large-scale engineering applications of membrane bioreactor technology.